How Our Knives are Made

From start to finish, it takes our artisans roughly 30 hours of careful and dedicated craftsmanship to create each knife we sell. For those of you who love the artistry as much as we do, here is an overview of how that process goes from start to finish.

Forging and Shaping

-

Base Forging

A piece of high carbon steel is heated to over 1000 degrees Celsius then hammered until thin and the desired shape using a belt hammer.

-

Tanzo Forging

A piece of soft iron is headed until red-hot, shaped against an anvil with a hammer, and welded to the edge of the high carbon steel blade.

-

Yakiire Tempering

After heading to a temperature of 750 degrees Celsius, the blade is cooled in water and reheated to 200 degrees to increase the steel's tenacity.

Sharpening and Polishing

-

Aratogi Rough Sharpening

The blade is pressed against a sharpening wheel using a wood frame to remove dirt from the metal, and sharpen the edge of the knife.

-

Kidoate Buffing

The knife is polished against a spinning sharpener made of pine tree to fix any deformations and bring out the metal's luster.

-

Bokashi and Finish

The surface of the steel blade is scrubbed using a rubber piece and powdered stone to create the hazy tarnish called kasumitoji.

Handle and Finishing

-

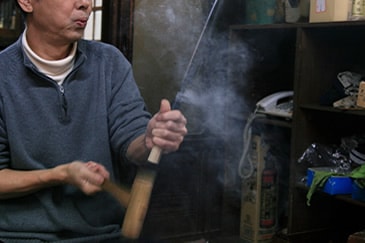

Heating Nakago

The iron tang of the blade is headed over a gas burner, avoiding the steel blade to minimize distortions, before the blade is attached to the handle

-

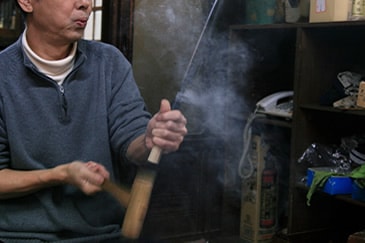

Etsuke Attaching Handle

The handle is pushed into place using a wooden mallet and attached to the metal part of the knife while it is still hot to create the perfect fit.

-

Correction and Polish

Any minor distortions from the nakago heating is corrected and the knife undergoes a final polish to make it ready for use by the chef.